Solar carports are becoming a popular way for homeowners and businesses to get clean energy and make good use of their outside areas. Unlike rooftop systems, a solar carport works as both a shelter for vehicles and a power generator. This reason is why many people are thinking about if solar carports are worth the money.

A solar carport makes the most of parking areas by turning them into energy sources. The panels are up high, so they don't have the same shading problems as rooftops. The structure also provides shade, which helps keep cars cooler in the summer and reduces sun exposure. For businesses, carports can make parking lots look better and make things more comfortable for customers and employees.

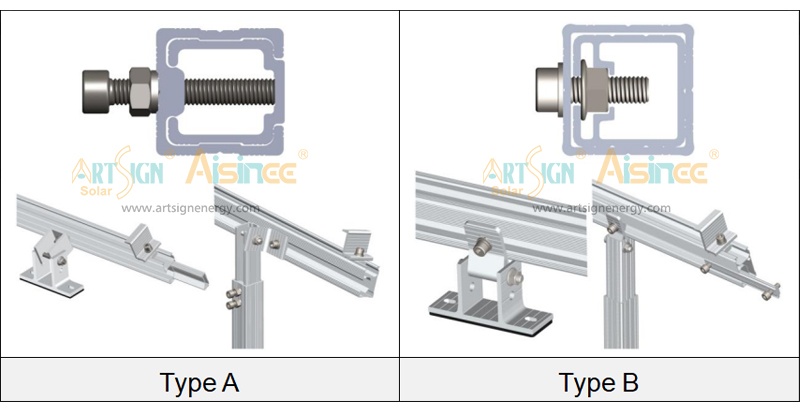

When it comes to making energy, carports tend to do better than rooftop systems. The angle of the panels can be set just right when they're installed. This lets them work better and put out more power. Rooftops can’t do this because of how they're built. Companies like SIC Solar make mounting systems. Their carport structures support good angles and last a long time. The systems keep the carport stable in wind, rain, and snow while still looking good.

Another good thing is that carports are easier to take care of. You can get to the panels from below, so you don't have to climb on a roof to clean them. For businesses, solar carports can be used with EV chargers. This makes a normal parking area into an energy station. This supports the need for electric cars and can make a business look more eco-friendly.

The price is the main issue, because solar carports require more steel and foundation work than rooftop systems. The money that can be saved on energy, and the extra benefits like car protection often make up for the cost. If a place has very little roof space, a carport might be the way to install solar.

For a home, work, or public space, solar carports give good value and a way to get renewable energy. With mounting solutions from companies such as SIC Solar, they’re a good choice for those looking to combine clean energy with infrastructure.