With the rapid advancement of the global photovoltaic market, installers and

owners—whether for commercial, industrial, or residential rooftop projects—face a common challenge: how to install more PV modules within a limited available area while achieving better overall energy yields. Although traditional south-north oriented single-tilt mounting systems are technologically mature, they often prove inadequate in high-latitude regions, on narrow rooftops, or in irregular terrains. This is because the large row spacing required to prevent shading leads to low utilization of land or roof space.

In such installation contexts, East-West Solar Mounting Systems have emerged as a transformative solution, standing out with their innovative design philosophy to enhance both space utilization and power generation efficiency.

Core system advantages: High-density arrangement and optimized power generation curve

The fundamental design concept of the east-west oriented system is to arrange photovoltaic modules like “roof tiles,” with a low tilt angle facing east and west in alternating rows. This design offers two key inherent advantages:

1.Fit Way More Panels On Your Roof: Because the rows run east-west, we completely sidestep the big north-south shadow problem you get with traditional setups. That means no more wasting huge gaps between rows just to avoid winter shading. The result? You can often pack 30-50% more panels into the same footprint. It’s a game-changer for commercial roofs where every square meter counts.

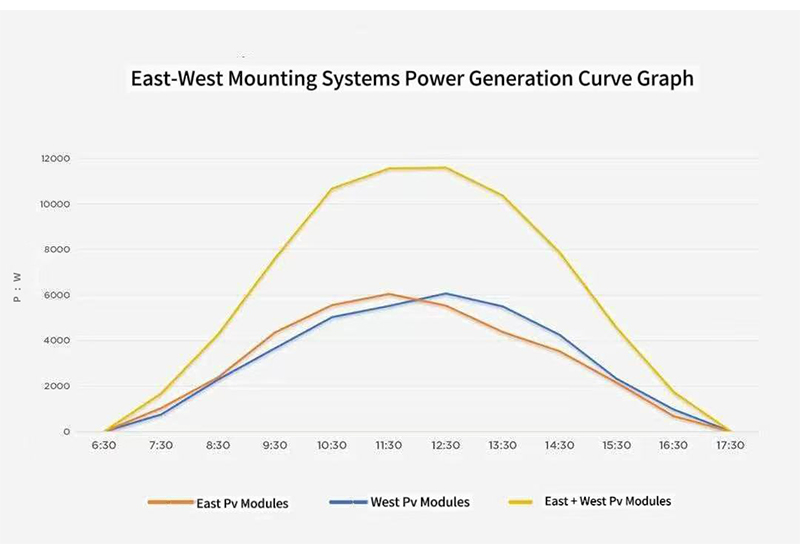

2.Power That Lasts All Day: Forget the big noon spike and sudden drop-off. East-facing panels catch the morning sun, west-facing ones grab the afternoon. Together, they stretch out your generation into a smoother, longer curve — easier on the grid and often a better match for your actual energy use. With the right Flat Roof PV mounting brackets, this balanced output comes with simpler mounting and less fuss.

Technical Specifications

Our are engineered to address diverse installation challenges, integrating the performance advantages of East-west Industrial Rooftop Solar Mounting into a design that prioritizes efficiency, reliability, and ease of installation.

Item

Specification & Description

Product name

East-West Solar Panel Bracket

Fixed Tilt Angles

10°, 15°, 20° (can be optimized based on project latitude)

Applicable Module

Suitable for both commercial and residential concrete flat roofs and the ground.

Certificate

ISO9001,TUV,SGS.CE...

Material

Anodized aluminum Al6005-T5

Service Life

20-25 years

Installation solutions for high-latitude regions and narrow roofs

For projects located in higher latitudes (such as northern Europe, northeastern China, Canada, etc.), the solar altitude Angle is relatively low. If the traditional north-south orientation is adopted, to avoid the shadow of the front row blocking the rear row, the required row spacing is very large, which may lead to a significant reduction in land utilization.The east-west oriented system, by utilizing a reduced tilt angle and eliminating north-south shading concerns, can increase the utilization rate to over 70%.

Similarly, for roofs with irregular shapes, numerous equipment obstructions, or limited depth, traditional long-row layouts are difficult to plan. The east-west system, with its short-row, High Density East-west Solar Panel Arrangement Mounting, offers exceptional flexibility.It can avoid obstacles and maximize the utilization of the roof area.

Streamlined Installation: Fewer Components Faster Deployment

Compared to traditional, complex adjustable mounting systems, the East-West Fixed-Tilt System features an exceptionally simple and clean structure.

Significant Reduction in Components: The system employs a modular, pre-assembled design, drastically reducing the number of on-site parts such as fasteners and rail connectors.

Greatly Simplified Installation Process: Installers are freed from complicated angle adjustments and spacing calculations. The primary tasks are streamlined to basic mount placement, rail laying, and module clamping, leading to a substantially faster installation speed compared to conventional systems. The shorter installation window reduces weather-related risks and saves on labor costs.

Future Trend: From "Power Output Optimization" to "Revenue Optimization per Unit Area"

As premium rooftop resources become increasingly scarce and the demand for grid-friendly power sources grows, the evaluation criteria for photovoltaic projects are shifting—from solely pursuing the "lowest cost per watt" to pursuing the "highest power generation revenue per unit area" and the "most grid-friendly output profile."

East-West Photovoltaic Mounting Systems are leading this transformation. Through systematic design innovation, they achieve an outstanding balance among spatial utilization, power generation profile, installation cost, and structural reliability. They are not just a mounting solution but an integrated system that comprehensively enhances project economics and grid compatibility.

As one of China's Top 20 solar mounting manufacturers, ArtSign integrates over 20 years of structural engineering expertise and deep insights into global markets into the design of every East-West mounting system. We are committed to continuous technological innovation, helping our clients overcome project constraints and harvest limitless energy from limited space.

Maximize the value of every ray of sunlight.

For any inquiry of solar panel mounting system, pls contact us, E-mai:sales@artsign.net.cn, Whatsapp / Wechat / Skype:+008618030235875, thanks.